POLYRISE’s coatings are based on a patented technology and a recognized expertise in sol-gel chemistry and polymer science to produce thin-film nanostructured layers that provide controlled optical, mechanical, barrier, or surface properties. Sol-gel is a soft chemistry process that allows the development of hybrid materials (inorganic-organic) such as glass matrices, in the form of hydroalcoholic solutions called SOL. After dip-coating or spraying, a sub-micron thin film called GEL is formed, meaning the gel state is obtained before cross-linking at a high or low temperature.

Designed for industrial purposes, our coatings deliver robust add-on features to optical fixtures, such as abrasion resistance and antireflective performance.

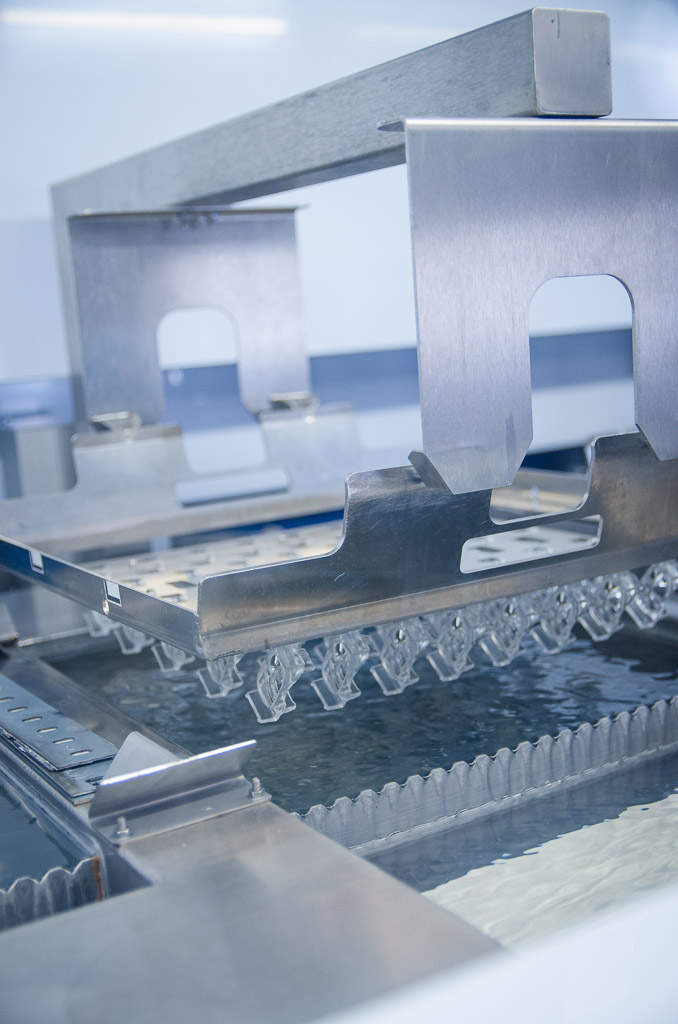

Customers’ substrates are coated in-house using fully automated, dust-free, ISO6 dip-coating lines. The importance of thin-film thickness control is guaranteed by an extreme accuracy and reproducibility of the substrate withdrawal from the coating bath. The process includes surface preparation, dip-coating, and pre-cure phases, prior to a final curing.